Main function

l Automatically adapt to the sampling mode according to the running state of the unit, and automatically identify the lifting speed, constant speed, load and normal running state of the unit;

l Steady-state analysis function: Time waveform, frequency spectrum, axis track, axis position, etc.;

l Condition monitoring function: Main monitoring diagram, vibrator diagram, trend diagram, etc.;

l Transient analysis function: Bode diagram, polar coordinate diagram, three-dimensional spectrum diagram, axis position, etc.;

l Unsteady analysis function: Wavelet gray map, Wigner distribution, short-time FFT transform, etc.;

l Fusion analysis of section: Vector spectrum, vector power spectrum, precession spectrum, etc

l Database function: Compress and store the data according to the running condition, and establish the running database and historical database of the unit for condition monitoring, fault diagnosis and trend analysis. The age of data storage depends on the hard disk capacity of the server, and data within 4 years can be saved with the permission of the server;

l Over-limit and alarm data automatic state identification, collection and recall function:

l Map and report output (customizable) function;

l Start-up, shutdown and transient process monitoring and analysis functions;

l Shafting mode analysis function;

l Fault diagnosis expert system:

l Multi-plane multi-measuring point dynamic balance test and settlement, result optimization function;

l Reserve the standard communication interface with SIS, CMMS or MIS, and connect with GPS interface (232, 485 or pulse) provided by the buyer to ensure the uniqueness and consistency of time.

Remote monitoring and diagnosis

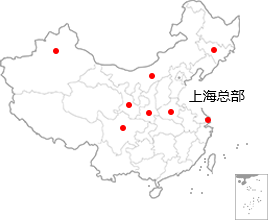

l Three-tier network structure, with remote monitoring and diagnosis ability, authorized users can access the system through local area network or internet through WEB to realize remote monitoring and diagnosis;

The system is equipped with remote diagnosis center interface, which can be connected with Shanghai Ruishi Technology Center without barriers, and participate in consultation with domestic famous industry fault diagnosis experts hired by our company.

Sensor / Transmitter Technology

Sensor / Transmitter Technology