Ruishi is a national high-tech enterprise specializing in the research, development, production and sales of the complete set of equipment technology for condition monitoring and protection of large-scale rotating equipment in petrochemical, metallurgical, electric power and other industries, as well as the management system of the IoT factory for equipment fault analysis and diagnosis. Since 2006, it has been rated as a national high-tech enterprise for 14 consecutive years.

Ruishi has a first-class standard vibration calibration table (low frequency table: 0.08Hz~200Hz; Intermediate frequency station: 5Hz~10KHz); Rotor test-bed for rolling and sliding bearings (real simulation of large equipment condition and fault signals); Eddy current sensor probe vacuum injection molding equipment, high and low temperature experimental equipment, pre-press molding equipment, numerical control processing equipment, laser welding equipment, laser lettering equipment, product high temperature aging room and product stability testing room.

A number of scientific research projects developed by Ruishi Vision and with independent intellectual property rights: The project of condition monitoring, vibration calibration and fault analysis system of large MW wind turbine based on wavelet analysis technology won the National Innovation Fund; The displacement / vibration detector of large rotating equipment won the National Innovation Fund; "Localization of large-scale unit safety condition monitoring and protection device system" won the technical innovation fund project of Shanghai science and technology small and medium-sized enterprises; "On-line condition monitoring and fault analysis and diagnosis system of large-scale wind turbines" won the research and development project of industry, university and research institute in Minhang District; "Development and Application of Key Technologies for Condition Monitoring, Analysis and Diagnosis of Internet of Things for Safe Operation of Large Rotating Equipment" won the research and development project of industry, university and research institute in Minhang District.

The key technologies and application projects of low-frequency fault diagnosis of large-scale wind turbine and hydropower units won the second prize of National Award for Science and Technology Progress; The complete set of online monitoring and diagnosis technology for ultra-low frequency faults of large-scale new energy generating units won the first prize of Shanghai Science and Technology Progress Award; The fault analysis and diagnosis system of large rotating machinery equipment won the second prize of Shanghai Science and Technology Progress Award; 1 project of Shanghai Torch Plan; 2 key new products in Shanghai. RS9000XL series eddy current sensor has obtained intrinsic safety explosion proof certificate (Certificate No.: CNEx19.4160X) and CE Certification (Certificate No.: CPC11/031887), the integrated vibration transmitter has obtained the intrinsically safe explosion-proof certificate (Certificate No.: CNEx18.5432);

The company has been granted 5 invention patents in the past 19 years; 10 utility model patents; 24 software copyrights; There are 11 high-tech achievements transformation projects in Shanghai.

Ruishi's main products at this stage: Complete set of device and networked factory management system of fault analysis and diagnosis for condition monitoring and protection of large rotating machinery in petrochemical, metallurgical and electric power industries; Networked system for condition monitoring, analysis and diagnosis of wind turbines: Series of eddy current sensors and transmitters; Piezoelectric / magnetoelectric speed sensor and transmitter series; Acceleration sensor series; Series configuration type condition monitoring and protection instrument device; Full-automatic condition calibration instrument series; Portable vibrometer, etc.

Ruishi has made great scientific research achievements in substitute. imported eddy current vibration / displacement sensors and transmitters, which have been converted into mass production. In which, a series of probes, extension cables and preambles of 3300 or 3300XL series eddy current sensors (φ5mm, φ8mm, φ11mm and φ25mm) of Bently company can be completely substituted with any parts. Ruishi series eddy current sensor probes are molded by three times of high temperature and high pressure vacuum injection molding process (which is completely consistent with Bentley process), which ensures the safety, stability, reliability and ultra-low temperature drift coefficient of the probes working for a long time. The eddy current sensor preposition produced by Ruishi adopts full digital debugging and temperature drift tracking compensation technology, which ensures the long-term stability of the sensitivity performance of the preposition. The linearity, sensitivity error, temperature drift coefficient, frequency / phase characteristics of the system can fully meet the technical performance indexes of the original eddy current sensor system of Bently Company after substitute. the sensor components of Bently Company. This product technology fills the technical gap in China.

Ruishi RS330500 can completely substitute BN330500 speed sensor; RS190501 can completely substitute BN190501 low frequency speed sensor; RS330400 can completely substitute BN330400 acceleration sensor.

Ruishi RS990 can completely substitute Bently Company's 990 two-wire eddy current vibration transmitter; RS991 can completely substitute Bently company's 991 two-wire eddy current displacement transmitter; Ruishi RS177230 completely substitutes Bently's 177230 vibration transmitter.

RS990/991 completely substitutes MX2034 vibration / displacement transmitter of METRIX company.

RS5521 completely substitutes MX5521 two-wire speed transmitter of METRIX company.

Ruishi RS5484E can completely substitute METRIX ST 5484 E; RS6917 can completely substitute ST6917 two-wire vibration speed transmitter of METRIX company, and directly output 4 ~ 20ma corresponding to vibration speed.

Ruishi RS102 and RS136 can completely substitute AC102, AC136 and AC135 acceleration sensors of CTC company; It can completely substitute Bently's 200350 and 200355 acceleration sensors. Completely substitute the acceleration sensor of the same specification of PCB company.

Ruishi RS6000 Rotating Machinery Condition Monitoring and Protection Instrument (combined with function card and frame), whose functions and technical indexes are completely equivalent to Bently3500 system, has been successfully and reliably applied in many large petrochemical, metallurgical and power industry units.

Ruishi RS8000 equipment fault analysis and diagnosis IoT factory management system has been successfully and reliably applied in many large petrochemical, metallurgical and power industry units.

Ruishi RS9000 networked system for condition monitoring, analysis and diagnosis of wind turbines has been matched with many main wind turbine manufacturers.

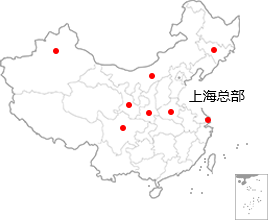

The company is committed to branding and internationalization of "Ruishi", and Ruishi will be market-oriented, strengthen new product research and development, and take technological innovation as the backup force; With the aim of survival by quality, development by innovation of new materials, new technologies and new processes, long-term development by honest and pragmatic attitude, benefit by good management and reputation by high-quality service, we unite as one, accumulate and forge ahead continuously, expand the domestic and international market share of "Ruishi" brand, and establish the image of "national high-tech enterprise" with its modern management mode.